Our Quality Standard

To ensure that every product reaches our customers in optimal condition, Lotus has established a standardized quality control checklist. Prior to shipment, each item is thoroughly inspected by our QC team in accordance with 06 defined criteria: Product Quantity – Product Form – Product Size – Fabric Quality – Fabric and Thread Color – Smocked and Embroidery.

Product Quantity

- Verified quantities and complete accessories as per order confirmation.

- Full compliance with all specified components and design requirements.

Product Form

- Ensure close alignment between Final products and Approved 2D outlines.

- Before finalizing the mock-up, the sales team provides detailed notes on design elements, along with reference images, to support clear and accurate design review.

- After sample completion and final production, detailed photos and videos are shared for client review and confirmation prior to shipment, ensuring transparency and alignment.

Product Size

- Lotus’s size charts align with international standards, particularly for the US and UK markets. However, to ensure the best fit for your target customers, we highly recommend using your own size chart when available.

- Our sales team provides close guidance during size chart selection to support accurate fit decisions.

- Products are reviewed on mannequins across multiple age ranges to ensure balanced proportions and overall fit.

Fabric Quality

- During consultation, our fabric catalog is provided, including updated fabric options and detailed specifications to support clear material comparison and selection.

- Final products undergo inspection to ensure no major visible fabric defects, including fraying, tearing, fading, or noticeable printing inconsistencies.

Fabric & Thread Color

- During the design stage, selected fabric and thread colors are confirmed based on Approved Color Charts or Images.

- For printed fabrics, test printing is available to allow clients to review and select preferred print results before bulk production. However, this service is not applied to sample orders or quantities under 20 pieces due to cost and supplier agreements.

- The sales team provides guidance to align fabric and thread colors as closely as possible with reference images.

Smocking and Embroidery

- Smocking foundations and embroidery threads are executed securely and consistently, in alignment with the approved embroidery sample.

- As each piece is fully hand-embroidered, natural variations may occur. Lotus aims for an overall finish and visual likeness compared to approved 2D designs and real product images, with embroidery that appears full, well-defined, and with minimal surface breakage or loose threads.

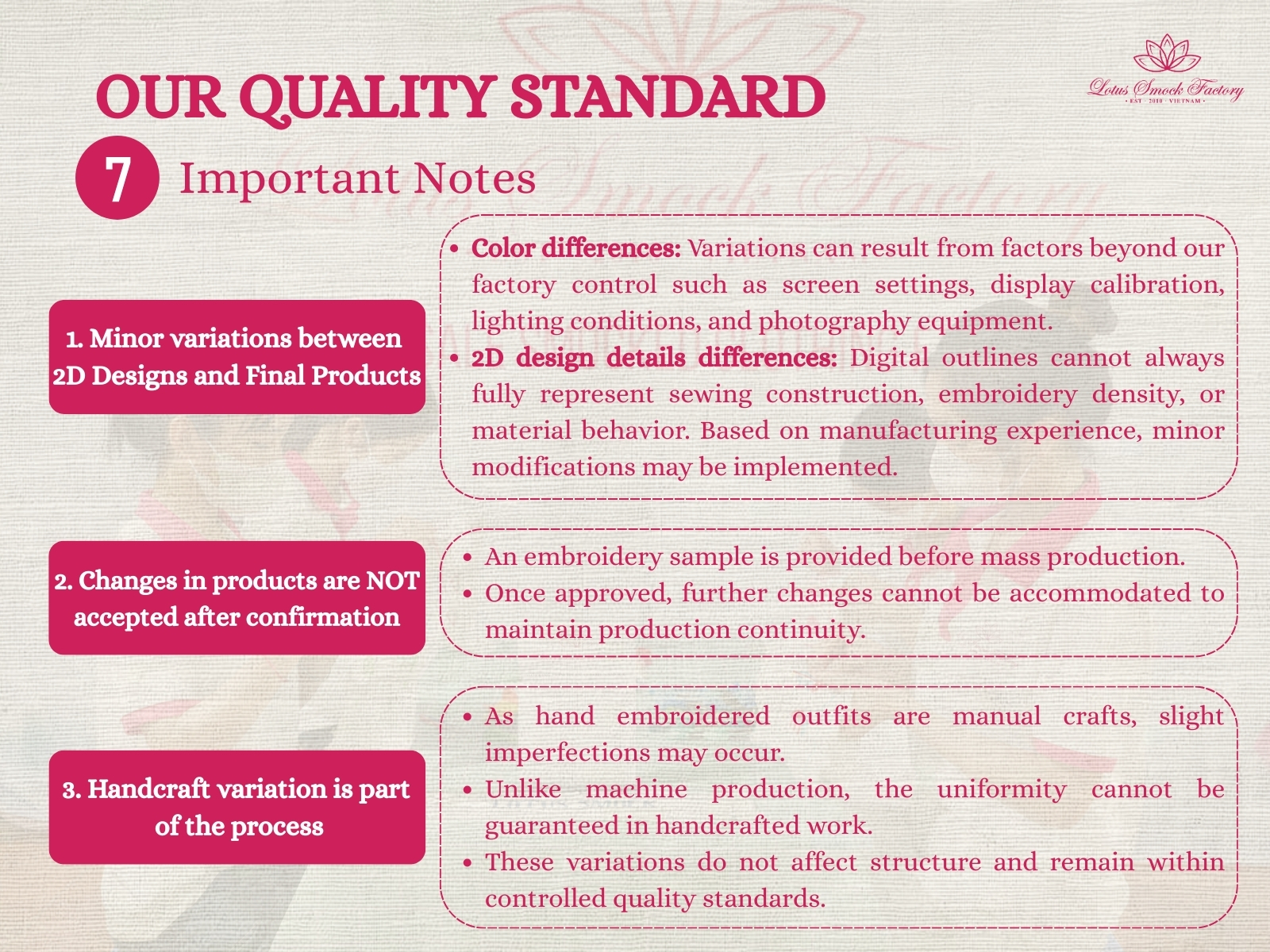

Important Notes on Product Quality

(1) Minor variations between 2D Designs and Final Products

- Color differences: Variations can result from factors beyond factory control such as screen settings, display calibration, lighting conditions, and photography equipment. To minimize color-related risks, color of products are confirmed through approved charts and sample reviews prior to mass production.

- 2D design details differences: Some structural elements shown in 2D mock-ups may require technical adjustments during production. Digital outlines cannot always fully represent sewing construction, embroidery density, or material behavior. Based on manufacturing feasibility and production experience, minor modifications may be implemented.

(2) Changes in products are NOT accepted after confirmation

- An embroidery sample is provided before mass production.

- Once approved, further changes cannot be accommodated to maintain production continuity.

(3) Handcraft variation is naturally part of the process

- As hand embroidered outfits are manual crafts, slight imperfections may occur.

- Unlike machine production, the uniformity cannot be guaranteed in handcrafted work.

- These variations do not affect structure and remain within controlled quality standards.