How to Calculate Embroidery Cost Per Stitch for Your Business

Embroidery cost per stitch represents businesses’ standard pricing approach for embroidery services. The number of stitches present in a design is the basis for business calculations that determine pricing rates and profit margins. The final cost depends on thread type, fabric selection, and design complexity. The comprehension of embroidery pricing enables retail businesses to control expenses while setting competitive market rates. This guide presents information about calculating embroidery cost per stitch alongside different pricing models and strategies to improve profits.

1. What is Embroidery Cost Per Stitch?

The pricing method called Embroidery cost per stitch enables businesses to determine embroidered design costs by counting the number of stitches needed. The pricing calculation helps businesses establish reasonable costs which include material expenses and labor costs as well as machine operation expenses. The more stitches in a design, the higher the cost due to increased production time and thread usage.

The accurate pricing of embroidery services depends on determining cost per stitch. The pricing method allows businesses to retain profitability and deliver competitive rates to their customers. The pricing method enables store owners and resellers to control their expenses properly and achieve optimal revenue outcomes in the embroidery business field.

2. Factors Influencing Cost Per Stitch

Embroidery cost per stitch depends on multiple elements that determine both pricing and business profitability. The identification of these elements enables businesses to establish competitive pricing that upholds quality standards.

Design Complexity and Stitch Count

The use of complex designs forces embroiderers to execute more stitches thus pushing up both production time and thread needs. The number of stitches required to create a simple logo falls below 5,000 but complex patterns often require more than 50,000 stitches thus affecting overall pricing.

Type of Thread and Fabric Used

The cost of specialty threads which includes metallic and polyester surpasses the price of standard rayon threads. The production process of thick or delicate fabrics needs adjustments that will slow manufacturing and increase expenses.

Machine Maintenance and Operational Costs

A commercial embroidery machine requires scheduled maintenance while its power consumption depends on its operating duration. The expenses are included in per-stitch pricing to secure the long-term sustainability of the business.

Labor and Time Investment

Operators who possess skills ensure that machines stitch with accuracy and maintain proper hooping and fix any encountered issues. Labor expenses change according to the requirements of manual assembly machine operation and final finishing work which affect total project prices.

3. Pricing Strategies for Embroidery Work

A suitable pricing model enables businesses to maintain profitability while competing effectively in the market. Different pricing approaches suit orders of different sizes design complexities and customer requirements.

3.1 Cost-Plus Pricing

A cost-plus pricing strategy adds profit margins to all production expenses to achieve business profitability. Businesses calculate:

- Material costs (thread, fabric, stabilizers)

- Machine expenses (maintenance, electricity)

The process requires both workforce participation and duration for setup operations and stitching procedures before completing the finishing steps.

An item with a total cost of $2.50 will become available at $3.75 when using a 50% markup calculation. The pricing system creates a steady profit margin for businesses.

3.2 Per 1,000 Stitches Pricing

Embroidery companies commonly determine their prices through the number of stitches in each design. The price for embroidery services varies from 0.50 dollars to 1.50 dollars for each 1,000 stitches and depends on design complexity.

Example pricing:

- 5,000 stitches → $2.50 – $7.50

- 10,000 stitches → $5.00 – $15.00

Custom order pricing works best through this approach since longer stitch counts need additional materials and production time.

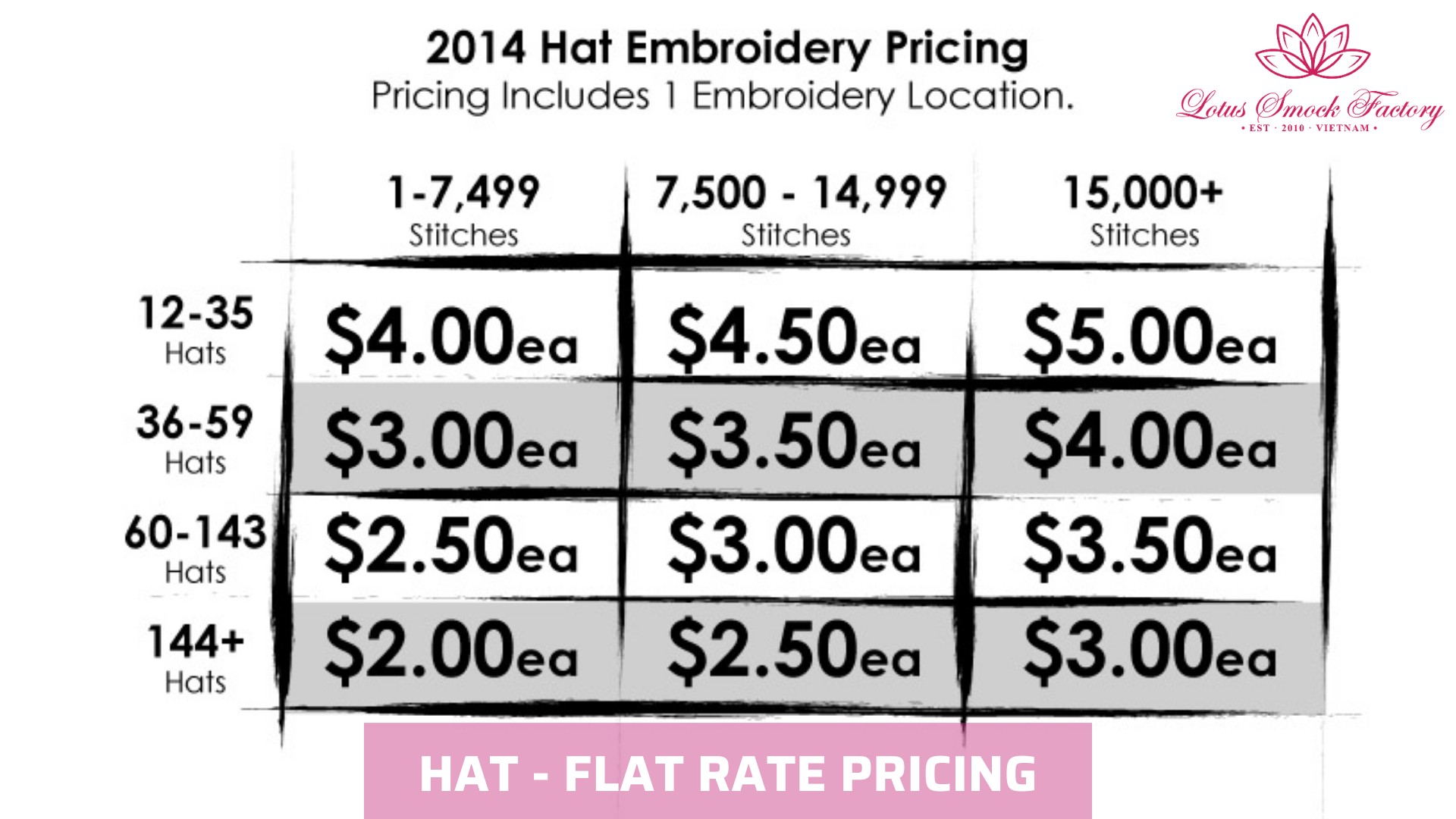

3.3 Flat Rate Pricing

Flat rate pricing makes it easy for customers to determine costs when ordering large quantities or basic design projects. Businesses establish standard pricing scales for regular products which include:

- Caps: $8 – $12

- Polo shirts: $10 – $20

- Jackets: $15 – $30

The pricing system provides straightforward rates and quick customer quotation services.

Price per stitch for embroidery of complex designs often results in underpriced products.

A company must choose its pricing method based on production capacity and business goals along with customer requirements.

4. Common Challenges in Pricing Embroidery Services

The establishment of embroidery prices extends beyond basic material expenditure and worker compensation. Businesses need to factor hidden expenses together with customer expectations to achieve profitability.

4.1 Underestimating Stitch Count

The proper assessment of stitch counts stands as an essential factor for determining prices. Underestimating leads to:

- Increased production time without proper compensation

- Higher thread and stabilizer costs

- Reduced profit margins

Tips for accurate stitch count estimation:

- The embroidery software allows businesses to determine precise stitch density values.

- The production team should execute test runs on complex design projects.

- The fabric material type requires special attention because thicker fabrics need additional stitches to achieve clear results.

4.2 Overlooking Overhead Costs

Businesses tend to concentrate on direct costs yet ignore operational expenses which include:

- Machine maintenance and depreciation

- Electricity and workspace rental

- Employee wages and administrative costs

The business should divide overhead costs into individual items to determine their impact on pricing. A shop that spends $500 on overhead expenses can maintain profitability by charging $0.50 additional price per item when producing 1,000 products each month.

4.3 Managing Customer Expectations

The pricing strategy faces challenges during interactions with customers who experience the following situations:

- Customers demand low costs but fail to grasp the connection between price and product value.

- Customers should not request bulk discounts because it does not account for production expenses.

- The price of embroidery work should be evaluated against commercial mass production costs.

How to handle this:

- The prices of embroidery products depend on the stitch count together with fabric type and custom design requirements.

- The business should provide different pricing rates for large-quantity orders to maintain its profitability levels.

- Showcase quality differences through the display of sample work

Businesses in the embroidery industry achieve profit stability by providing clear pricing information and accurate cost assessments.

5. Solutions Through Effective Pricing Models

The selection of appropriate pricing strategies for embroidery allows businesses to maintain competitive positions while achieving profit targets. Businesses that use structured pricing models decrease pricing errors while ensuring their rates match market conditions.

5.1 Utilizing Embroidery Pricing Calculators

The online embroidery pricing calculators enable businesses to determine precise costs through their ability to integrate the following factors:

- Stitch count

- Thread type and fabric costs

- Machine and labor expenses

- Overhead and profit margins

Benefits of using pricing calculators:

- Saves time by automating calculations

- The implementation of pricing calculators prevents mistakes made by human estimators when setting prices.

- Online embroidery pricing calculators enable businesses to provide customers with steady pricing rates.

Embroidery software programs Wilcom and Hatch come equipped with pricing tools that help users create precise job estimates.

5.2 Implementing Tiered Pricing Structures

The pricing system allows businesses to offer discounts for bulk purchases without jeopardizing their profit margins. Businesses can offer:

- Per-unit discounts: Reduced rates for larger orders (e.g., $5 per piece for 10 units, $4 per piece for 50 units)

- Package deals: Bundling services like digitizing, embroidery, and finishing at a set price

- Premium pricing for custom work: Higher rates for detailed, labor-intensive embroidery

The combination of different prices enables businesses to gain new customers and maintain profitability when dealing with large orders.

5.3 Regularly Reviewing and Adjusting Prices

The profitability of businesses depends on market price changes affecting fabric materials and thread supplies as well as labor wages. Regular pricing reviews help businesses:

- Adjust for inflation and supplier cost changes

- Stay competitive with industry-standard rates

- Identify underpriced services that cut into profits

Businesses can sustain their operations through price model reviews which happen twice yearly to adapt to industry trends.

“Contact Lotus Smock at:

- Facebook: facebook.com/lotussmockfactory

- WhatsApp: +84 83 333 3498

- Youtube: youtube.com/@LotusSmockFactory”

Businesses that understand how to price embroidery work benefit from both market competitiveness and financial success. The process of accurate calculation helps businesses avoid underpricing their products while maintaining fair labor and material expenses. Through cost-per-stitch pricing methods, resellers along with store owners can expand their operations while drawing in additional customers. Your company should start reviewing embroidery pricing as a means to boost profitability while sustaining service quality.