Cotton Embroidery Suits Wholesale Guide from A to Z in 2025

Cotton embroidery suits are becoming an increasingly attractive choice for wholesale businesses thanks to their sustainable materials, intricate handcrafted designs, and high profit potential. In particular, the demand of trading cotton embroidery baby suits has significantly increased among both retailers and wholesale importers. If you’re looking to expand your product range with high-value items, this kind of the cotton embroidery suits wholesale market is a strong contender. This guide covers everything from product features, popular styles, pricing and quality standards, to supplier evaluation and importing insights, equipping wholesalers with a comprehensive foundation for successful sourcing and market entry.

1. Updated Information about Cotton Embroidery Suits Wholesale

Understanding the fundamental characteristics of the product and the market is crucial before committing to wholesale sourcing. Businesses that grasp why cotton embroidery baby suits are in demand, what styles sell best, and how to assess pricing in relation to quality will be better positioned to make profitable decisions.

1.1. Cotton Embroidery Baby Suits Are Favored

The global fashion industry has seen a marked increase in the demand for ethnic and fusion apparel, with cotton embroidery suits leading the charge. Markets in North America, Europe, and the Middle East have embraced these garments for their skin friendliness, cultural resonance and stable profit margins:

- Skin friendliness: One of the primary reasons these suits are so favored is their unmatched comfort and breathability. Crafted predominantly from high-grade cotton, these garments are soft to the touch and naturally hypoallergenic, making them ideal for delicate baby skin. The embroidery, while adding a layer of visual appeal, is designed in a way that does not compromise the garment’s comfort. This harmonious balance between function and fashion enhances the value perception among end consumers, especially new parents who prioritize both aesthetics and safety for their children.

- Cultural resonance: These suits align well with cultural and seasonal preferences across many markets. In regions where gifting baby clothes during holidays or festivals is customary, embroidered designs tailored to themes like New Year or Christmas are particularly in demand. As a result, the suits become not just clothing items, but symbolic gifts with cultural resonance. This dual value practicality and sentiment helps retailers drive seasonal promotions and maximize inventory turnover.

- Stable profit margins: Retailers also benefit from the product’s relatively stable profit margins. Since babywear tends to have a high repurchase rate due to rapid growth in infants, loyal customers often return for larger sizes or new collections. This ongoing demand, coupled with the timeless appeal of embroidered cotton, creates opportunities for repeat sales and strong customer retention.

1.2. Popular Baby Types of Cotton Embroidery Suits Wholesale

The babywear market is highly segmented by style, and embroidery elevates each design category with unique textures and patterns.

- For girls:

When it comes to favorite types of cotton embroidery suits wholesale for baby girls, there are some famous names such as dress-style bodysuits, bumble, rompers and swimsuits. Each bestselling style for baby girls is particularly favored for their ease of use relating to season and climate, for instance, bumpers and swimsuits are so famous in warm climates or in summer, balancing cuteness with cooling comfort.

The dress-style bodysuits have become a staple. These often feature floral, lace embroidery, Disney princess patterns or heart-shaped on soft cotton, giving a delicate yet playful look suitable for both casual and formal occasions. In addition, rompers and swimsuits, specifically favored for their charming patterns, such as animals or fairytale themes embroidered on the chest or cuffs.

- For boys:

In terms of baby boys, preferences lean toward practical yet stylish pieces such as loungewear sets, longhalls and shorthalls. Understanding the nuanced appeal of each style helps wholesalers build a diverse product portfolio that resonates with different consumer segments and cultural expectations.

While loungewear sets are increasingly favored by modern parents looking for comfort-focused outfits, it often includes soft joggers and tops with minimalist embroidery. These structured one-piece garments often feature classic embroidered motifs such as trucks, animals, or sports icons, positioned strategically to draw attention without overwhelming the design. Meanwhile, two-piece outfits allow for more flexibility in pairing and customization, with embroidered logos or initials adding a subtle brand identity or personal touch.

1.3. Pricing & Product Quality When Buying in Bulk

Sourcing babywear at scale requires a delicate balance between cost efficiency and uncompromised quality. One of the first aspects to consider is the Minimum Order Quantity (MOQ) set by suppliers. Normally for cotton embroidery suits wholesale, lower MOQs (approximately 30) offer flexibility for newer or smaller businesses, whereas higher MOQs (ranging from 100 to 200) usually come with volume-based discounts. Establishing a clear understanding of discount structures allows importers to plan inventory investment and forecast margins more accurately.

Beyond price, fabric quality and embroidery standards are critical. Products should ideally use certified cotton or other recognized eco-friendly materials to meet international safety standards. The embroidery must be tightly stitched, with vibrant and fade-resistant threads to ensure longevity through multiple washes. The consistency of the needlework, the symmetry of design, and the finishing of seams are all indicators of production excellence.

Customization services play a key role in differentiating a wholesale business. Many suppliers offer private labeling, tag printing, or bespoke embroidery to match brand themes or regional aesthetics.

By leveraging such services, importers can increase perceived value and create a stronger brand identity without altering the core product significantly. This flexibility is especially useful in competitive markets where visual differentiation can influence buying decisions.

2. Key Considerations When Choosing Suppliers for Cotton Embroidery Suits Wholesale

Sourcing cotton embroidery baby suits in bulk involves more than just finding a good-looking product at a competitive price. The supplier you choose will directly impact your brand’s reputation, customer satisfaction, and long-term profitability. Reliable manufacturers don’t just deliver garments, they provide consistency in quality, production flexibility, and clear communication throughout the process. That’s why selecting the right partner is just as crucial as selecting the right product. Below is a detailed checklist of the most important factors to evaluate when choosing suppliers for cotton embroidery baby suits:

2.1. Manufacturing Capability: Factory vs Trading Company

One of the most critical decisions is determining whether your potential supplier is a factory or a trading company. While trading companies may offer more product variety at the outset, working directly with a manufacturing factory provides significant advantages for B2B buyers. Factories offer better control over product quality, shorter feedback loops during customization, and more room for negotiation on pricing due to fewer intermediaries. Moreover, a direct relationship with the production unit enhances transparency, which is especially vital in baby clothing where safety, compliance, and material sourcing are non-negotiable.

To verify manufacturing capability, ask for business licenses, factory audit reports, or even live virtual tours of the production line. A legitimate factory will have no issue sharing credentials or showcasing their setup.

2.2. Product Range, Design Capacity & Customization Options

In today’s fast-paced fashion cycle, variety and trend alignment are critical. A good supplier should offer a wide range of cotton embroidery baby suits wholesale in different styles, age groups, seasonal themes, and embroidery techniques. Look for those who follow market trends and release updated collections regularly, as this indicates a dynamic and responsive design team.

Even more important is the ability to customize. From fabric selection and color palettes to embroidery placement and baby-safe trims, customization enables your brand to offer unique points that stand out. Ask if the supplier can accommodate small-scale sampling, prototype development, or private labeling, which are crucial for developing your own line or testing market response.

2.3. Pricing Structure and Transparency

While price competitiveness is a natural priority in wholesale buying, the lowest price doesn’t always equate to the best deal. Evaluate pricing in the context of fabric quality, embroidery detail, stitching durability, and compliance with babywear safety standards. Be cautious of quotes that seem “too good to be true” as they often come at the cost of shortcuts in material sourcing or labor ethics.

Ensure that the pricing structure includes a clear breakdown such as fabric costs, embroidery charges, packaging, and freight options. Reputable suppliers are transparent and willing to explain how the cost per unit is calculated, especially for custom or bulk orders.

2.4. Business Policies: Returns, Defects, and Payment Terms

Understanding a supplier’s business policies is essential before entering a long-term contract of cotton embroidery suits wholesale. A supplier’s willingness to take responsibility for defects or late deliveries speaks volumes about their professionalism. Look for clear policies on:

- Return and refund protocols for defective batches

- Reproduction timelines for faulty or missing pieces

- Deposit percentages and final payment timelines

- Intellectual property protection for custom designs

A well-structured and mutually agreed-upon policy document is key to preventing disputes and ensuring accountability on both sides.

2.5. Lead Times and Production Flexibility

Efficient lead times are especially important in the children’s apparel sector, where designs are frequently updated and new launches are tied to seasonal trends or promotions. Ask the supplier of cotton embroidery suits wholesale for a clear timeline from sample development to final production and shipping.

Lead times will vary depending on order volume, complexity of embroidery, and sourcing of specific fabrics or trims. However, reliable factories will have well-organized production workflows that minimize delays, offer real-time updates, and even accommodate rush orders when needed.

Production flexibility is another underrated but valuable trait. A supplier that can scale production up or down, modify designs mid-process, or adjust to your evolving product specs is one that can grow with your business.

After-sales support is a critical yet often overlooked element in supplier relationships. Good suppliers stay engaged beyond the shipment phase, providing assistance with documentation, managing potential disputes, and adjusting future orders based on feedback. A supplier’s willingness to collaborate and adapt often reflects their commitment to long-term partnerships rather than one-off transactions.

2.6. The Origin of Factory

The geographical origin of a manufacturing facility plays a critical role in determining everything from unit pricing and product quality to labor standards and production capacity. Regional differences in infrastructure, labor costs, and raw material availability can significantly impact your bottom line, and as such, should never be overlooked when vetting a supplier.

For instance, factories in Western countries such as the U.S. or parts of Europe often guarantee high labor standards and advanced automation, but come with significantly higher costs, lack of advanced experience in terms of producing handicrafts making them less feasible for most cotton embroidery suits wholesale buyers. Meanwhile, some regions in the Middle East or Africa may offer low prices, but often lack the textile specialization, consistent quality control, or large-scale embroidery expertise that babywear requires.

Asia, however, remains the undisputed leader in textile manufacturing. With decades of industry experience, vast skilled labor pools, and competitive production pricing, countries like China, India, and Bangladesh dominate global exports in garments, especially cotton-based products.

But within Asia, Southeast Asia, and particularly Vietnam, has emerged as a standout sourcing destination in recent years. The country’s growing investment in textile infrastructure, coupled with a skilled labor force and traditional embroidery techniques, makes it ideal for producing high-quality cotton embroidery suits at competitive prices.

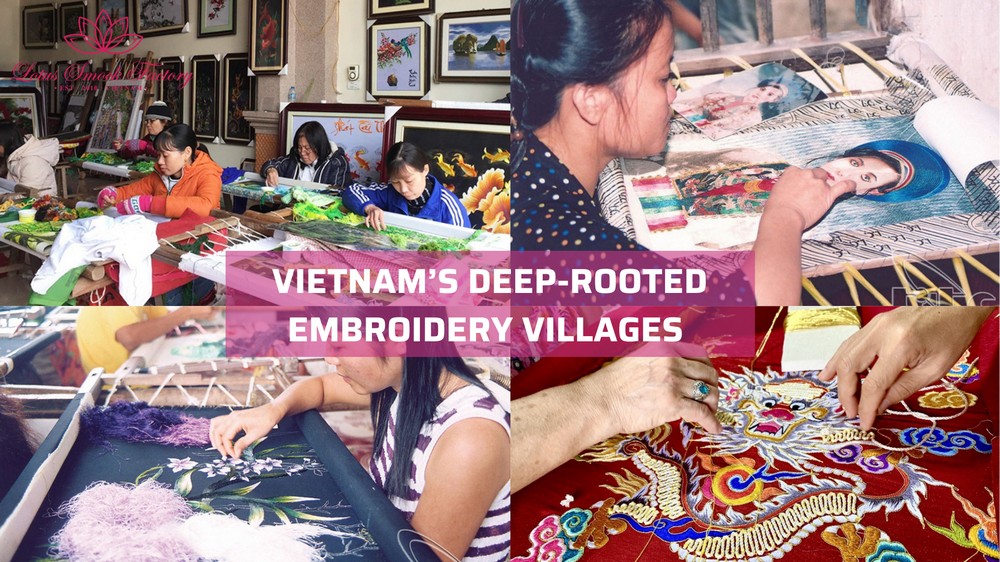

Vietnam’s deep-rooted embroidery culture is best exemplified through its centuries-old craft villages such as Quất Động (Hà Nội), Vạn Phúc (Hà Đông), and Thường Tín (Hà Nội). These villages are known for producing hand-embroidered textiles that require meticulous craftsmanship passed down through generations. Their artisans specialize in detailed motifs, delicate stitching, and natural dye techniques that reflect not just skill but cultural heritage, making them uniquely suited to babywear that demands both quality and gentleness.

Vietnamese suppliers often offer a favorable blend of craftsmanship and scalability. Unlike high-volume Chinese factories that may sacrifice attention to detail for speed, Vietnamese manufacturers tend to prioritize workmanship, especially in niche categories like baby embroidery suits. This translates into products that not only meet but often exceed the expectations of Western buyers. Additionally, Vietnam benefits from several free trade agreements (FTAs), which can reduce import duties and expedite shipping to key markets like the EU, Japan, and the US.

3. Top 3 Trusted Factory for Cotton Embroidery Suit Wholesale

Choosing the right manufacturer for cotton embroidery suits wholesale is not a one-size-fits-all decision. Depending on your business model, target market, and product vision, different suppliers may bring different strengths to the table. Some brands prioritize artisan-level quality and customization, while others focus on scalability and pricing. The following three factories have been selected to reflect the diversity of strengths across different sourcing goals.

3.1. Lotus Smock (Vietnam)

Lotus Smock stands as a beacon of Vietnamese artisanal excellence in the realm of cotton embroidery baby suits. Situated in Hanoi, the factory seamlessly blends traditional hand-smocking techniques with modern production capabilities, catering to both boutique retailers and larger wholesalers.

When it comes to key strengths:

- Authentic Manufacturing Facility: As a bona fide manufacturer, Lotus Smock offers direct oversight of the production process, ensuring stringent quality control and the ability to accommodate customizations efficiently.

- Diverse and Trend-Responsive Product Range: The factory boasts a wide array of designs, regularly updated to reflect current market trends, and offers extensive customization options, including fabric selection, color palettes, and embroidery patterns.

- Transparent and Competitive Pricing: With a minimum order quantity (MOQ) of approximately 30 pieces per style, Lotus Smock provides flexibility for various business sizes. Pricing ranges from $15 to $30+ per unit, with potential discounts for larger orders.

- Robust Business Policies: The company maintains clear policies regarding returns, defects, and payment terms, fostering trust and long-term partnerships.

- Efficient Lead Times: Standard production lead times are around 4-6 weeks, with the capability to expedite orders as needed.

- Cultural and Geographical Advantage: Vietnam’s rich heritage in embroidery, exemplified by villages like Quất Động and Vạn Phúc, imbues Lotus Smock’s products with unparalleled craftsmanship. Additionally, Vietnam’s participation in multiple free trade agreements facilitates smoother international trade.

Regardigns considerations: While the focus on quality and craftsmanship is paramount, it may result in slightly higher costs compared to mass-production factories.

Contact Lotus Smock at:

Facebook: facebook.com/lotussmockfactory

WhatsApp: +84 83 333 3498

Youtube: youtube.com/@LotusSmockFactory

3.2. Jiangmen Ji Anli Garment Co., Ltd. (China)

Located in Guangdong, China, Jiangmen Ji Anli Garment Co., Ltd. is a seasoned manufacturer specializing in baby and children’s apparel, including cotton embroidery baby suits.

First, about key strengths:

- Established Manufacturing Entity: With over two decades of experience, the factory operates multiple production lines, ensuring scalability and consistency.

- Extensive Product Portfolio: Offers a broad selection of baby garments, accommodating various styles and customization requests.

- Competitive Pricing Structure: FOB prices range from $1 to $3 per unit, with an MOQ of 2,000 sets, making it an attractive option for large-scale orders.

- Compliance and Certifications: Holds verified business licenses and has undergone third-party audits, ensuring adherence to industry standards.

About considerations: Higher MOQs may not be suitable for smaller businesses or those testing new markets. Moreover, while cost-effective, the emphasis on volume may impact the level of detail and customization available.

3.3. Banjaran (India) – Fusion of Traditional Artistry and Contemporary Design

Banjaran, based in Jaipur, India, is renowned for its handcrafted garments that marry traditional Indian embroidery techniques with modern aesthetics.

Regardings key strengths:

- Artisanal Manufacturing Approach: Collaborates with local artisans to produce unique, hand-embroidered baby suits, reflecting India’s rich textile heritage.

- Design Innovation: Combines Western design sensibilities with traditional craftsmanship, resulting in distinctive products that stand out in the market.

- Ethical and Sustainable Practices: Committed to slow fashion principles, ensuring fair labor practices and sustainable production methods.

In terms of considerations: The artisanal nature of production may lead to longer lead times and higher costs compared to mass-production factories. Also, limited scalability might pose challenges for large-volume orders.

4. Importing Cotton Embroidery Baby Suits: Tips for International Wholesalers

Navigating the import process smoothly can significantly influence your margins, customer experience, and supply chain stability. For cotton embroidery suits wholesale, proper planning, beyond just logistics, is essential to avoid delays, capitalize on trends, and maintain healthy inventory cycles.

4.1. Lead Time & International Shipping: Plan Well in Advance

Unlike basic textile products, embroidered baby garments require more time to produce due to the complexity of smocking, hand-stitching, or custom embroidery work. Standard lead times for production typically range from 3 to 5 weeks, depending on the volume and level of customization. Add to that international shipping such as via air or sea, and total delivery time can stretch to 8 – 10 weeks or longer.

To mitigate delays and avoid missed sales opportunities, especially during key seasons like Christmas, Easter, or back-to-school, wholesalers are advised to:

- Place orders at least 3 – 6 months in advance of peak sales periods. This includes accounting not only for production and shipping but also for marketing and campaign preparation time.

- Align with your marketing calendar photography, content planning, and promotion should begin as soon as samples or first batches arrive.

- Consider running an initial small order for photo shoots and sample promotions. This allows you to showcase the actual product to retail buyers or end-customers before committing to larger volumes.

4.2. Trend Forecasting: Be Proactive with Fabric & Pattern Planning

Beyond production logistics, smart cotton wholesale suits wholesale buyers go one step further by researching design trends and consumer preferences in advance. With cotton embroidery suits, fabric prints, color palettes, and embroidery patterns play a huge role in purchase appeal.

Rather than relying solely on supplier catalogs, you can gain a competitive edge by:

- Studying upcoming fashion trends for babies and toddlers in target markets (e.g., floral prints, pastel tones, vintage embroidery themes).

- Suggesting your own custom fabric prints or embroidery motifs to manufacturers, many suppliers in Vietnam and Southeast Asia are open to custom requests for a reasonable MOQ.

- Reviewing seasonal demand cycles and top-selling styles from previous years to guide your new collections.

This proactive approach not only boosts your product appeal but also strengthens your supplier relationship by showing clear vision and long-term intent.

4.3. Post-Arrival Content Creation: An Essential Sales Phase

Many retail customers, especially parents buying baby wear prefer to see the actual product before making a purchase. That’s why receiving inventory is just the halfway point in your selling cycle.

Once your imported stock arrives, invest in high-quality product photography showing detailed embroidery, fabric texture, and fit. Next, creating lifestyle visuals or videos that resonate with parents such as real babies wearing the outfits in natural settings can significantly boost conversions. In addition, it can be more beneficial thanks to using this fresh content in targeted ad campaigns, email marketing, and social media channels to drive sales.

In short, while pre-order strategies help sellers test market response, it’s the post-arrival marketing push that truly moves inventory and builds brand trust.

Navigating the import process smoothly can significantly impact delivery timelines, profit margins, and customer satisfaction. With the right preparation, businesses can mitigate common risks and streamline cross-border operations.

5. Common Risks and How to Vet a Reliable Cotton Embroidery Suits for Wholesalers

When sourcing cotton embroidery suits wholesale, especially from overseas suppliers, wholesalers face a range of risks that can directly impact cost, delivery timelines, and brand reputation. Understanding these risks and proactively mitigating them is crucial for securing a sustainable, trustworthy manufacturing partnership.

5.1. Common Risks in Sourcing

- Scams and Fake Suppliers: One of the most damaging risks is falling victim to scams. This usually happens when wholesalers place a deposit or full payment to a supplier who turns out to be fraudulent. These entities often pretend to be legitimate manufacturers, using fake business licenses, websites, or social media pages. Once the payment is received, communication ceases, and no goods are ever delivered.

- Poor Quality or Misrepresented Products: Even if the supplier is real, there’s still a substantial risk that the actual products received are of poor quality or differ significantly from what was advertised or promised. This includes:

Subpar embroidery or smocking work

Use of low-grade or unsafe fabrics

Incorrect sizing or stitching issues

Deviations from custom requirements or design specs

In the babywear market, where quality and safety are non-negotiable, such issues can severely hurt your brand’s credibility and lead to costly product recalls or customer dissatisfaction.

5.2. How to Vet a Reliable Supplier: Practical Solutions

Finding a trustworthy supplier is one of the most critical steps for any business importing cotton embroidery baby suits wholesale. A supplier may present well online, but without careful vetting, issues like inconsistent quality, delayed shipping, or even scams can arise. To minimize risk and build a dependable supply chain, it’s essential to evaluate potential partners before, during, and after production.

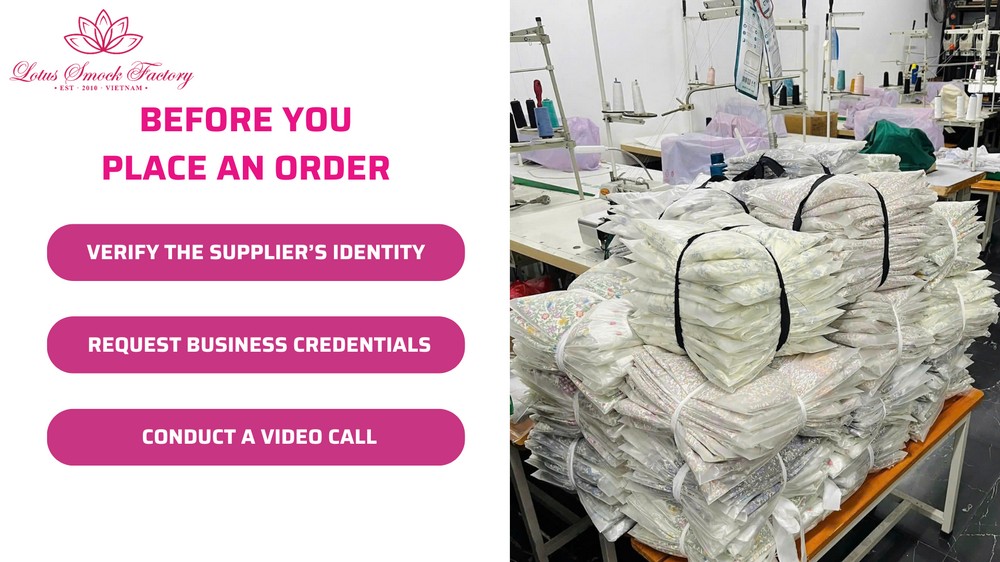

5.2.1. Before You Place an Order

- Verify the Supplier’s Identity: Check their presence across trusted platforms (Alibaba, Global Sources, Made-in-China, etc.), review customer feedback, and confirm that their website and social media profiles are active and consistent.

- Request Business Credentials: Ask for official business licenses, certifications (like OEKO-TEX for fabric safety), factory photos, and references from previous international clients.

- Conduct a Video Call: Always schedule a live video call with the supplier to confirm they actually operate a physical factory. Ask them to walk through their workspace or show you real-time footage of their embroidery, smocking, or fabric storage areas.

5.2.2. During the Production Process

- Request a Pre-Production Sample: Never proceed to mass production without a physical sample that you’ve checked for quality, fabric softness, stitching, sizing, and embroidery precision.

- Track Key Production Stages: Stay involved throughout the order timeline. Ask the supplier to send updates and videos or photos of important steps, fabric selection, pattern cutting, smocking, embroidery, stitching, packaging.

- Use Quality Control Services: Consider hiring a third-party QC agent (such as SGS, Intertek, or a local agency) to inspect batches during and after production.

5.2.3. After Delivery – Set Clear Warranty & Return Policies

Ensure all policies are agreed upon in writing beforehand: return conditions, warranty coverage, defect handling, and compensation timelines. In addition, choosing suppliers for cotton embroidery suits wholesale who are responsive post-sale and open to resolving complaints professionally is also essential, this is often a sign of long-term partnership potential.

By staying vigilant before, during, and after production, wholesalers can dramatically reduce risk and establish reliable, high-quality supply chains. Cotton embroidery baby suits require not only aesthetic appeal but also strict attention to fabric quality and craftsmanship. Partnering with a well-vetted manufacturer ensures both product excellence and peace of mind.

Choosing the right supplier in cotton embroidery suits wholesale is not just a one-time task, it’s an ongoing process that impacts your brand reputation, customer satisfaction, and long-term growth. By following the steps above, you can confidently source from partners who align with your quality standards and business values.

If you’re looking for a reliable manufacturing partner, contact Lotus Smock Factory to explore custom solutions, competitive pricing, and fast lead times tailored to your business needs.